By the Workshops Core Lab team and Caitlin Clark

Protective face shields and safety screens are important healthcare infection mitigation strategies utilized during the COVID-19 pandemic. They are cheap, quick to manufacture and simple to assemble, and face shields may be worn for long time periods and are easily cleaned and re-used. When used in combination with social distancing, good hand hygiene and face masks, they represent a key part of COVID-19 infection prevention.

Through the design and production of face shields and safety screens in the KAUST Workshops Core Lab, team members there are helping address community safety concerns during the pandemic and as people adjust to a “new normal” on campus.

Partnering with industry for face shields

In late March, KAUST senior management requested the Workshops Core Lab to begin manufacturing face shields according to a design provided to the University by McLaren Racing. KAUST and McLaren previously began a partnership in 2018 to focus on research and development in extreme performance technology.

“The McLaren design involved 3D printing of a headband, which is a semi-circular band of 3 millimeter-thick plastic with ‘nodules’ on which to fix the clear plastic shield,” explained Martin Glasspool, lead production engineer, Workshops Core Lab. “There is also a shaped band approximately 40 millimeters back from the front band that is in contact with the forehead. The band gives the clear visor a distance from the nose and mouth and prevents fogging from breathing.”

A KAUST Health staff member showcases the proper use of a University-produced face shield and a face mask and other protective coverings in the clinic on campus. File photo.

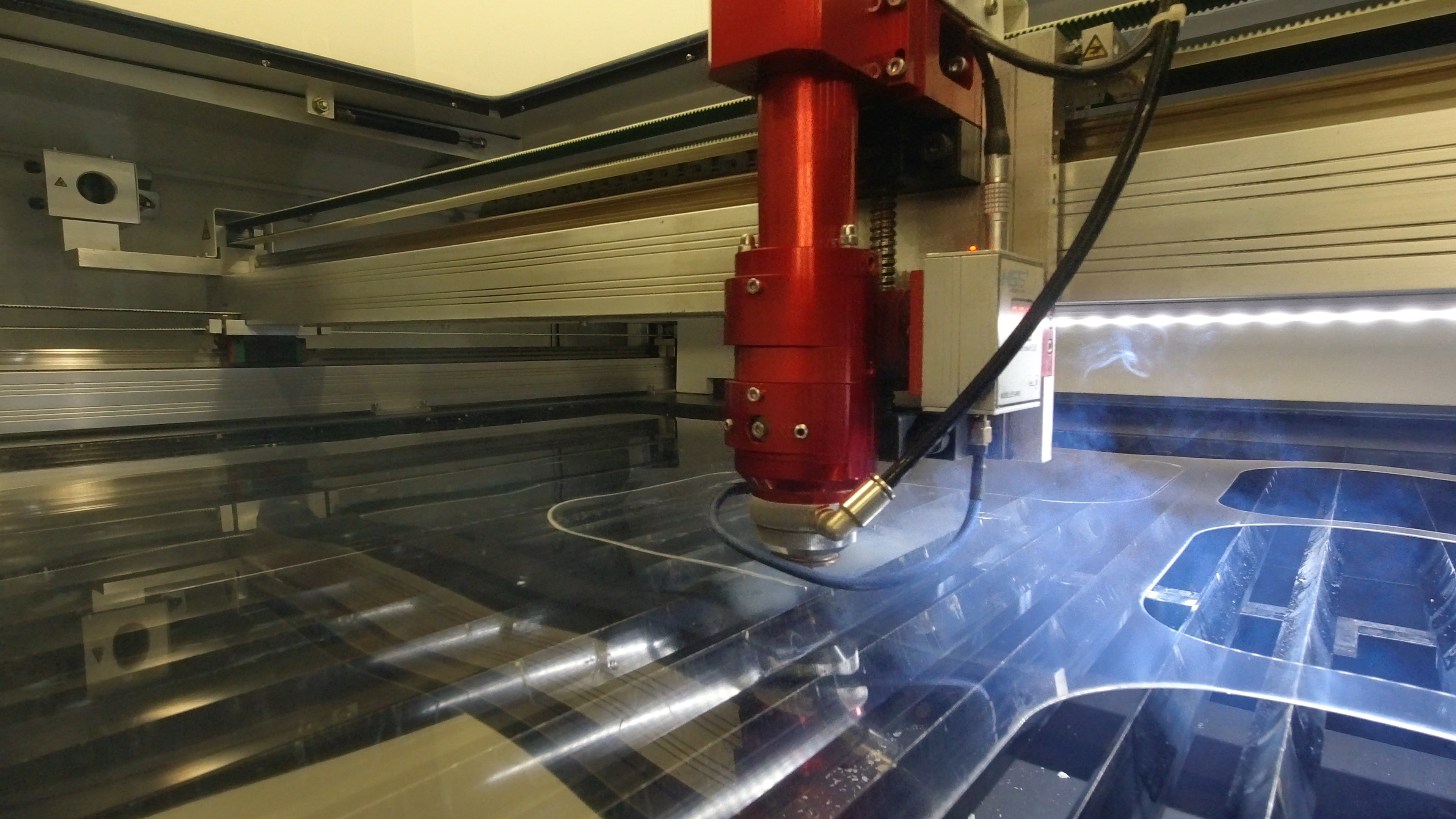

“The Workshops Core Lab’s laser cutting machine was used to cut the clear face shield part of the design and the silicone fixing straps, and all 3D printers in the Workshops Core Lab were used to print the headbands,” he continued.

Around 100 McLaren-designed face shields were then distributed to KAUST Health, the on campus clinic, with these “extremely well-received and further orders for over 50 more from KAUST Health requested after the initial delivery,” Glasspool noted.

Improving designs on campus

The Workshops Core Lab team also experimented with five other face shield designs, examining different options that were lighter, which feels better for the user, and quick to produce. Several designs were initially manufactured, and over 50 of the Core Labs-designed face shields were also provided to KAUST Health and to the Saudi National Guard Hospital for their trialed use.

“A U.K. makerspace website put out a cheap, quick design for all to use for free on their website, and the development of the design was progressed in the Core Labs,” Glasspool said. “The other design we focused on is what we call the ‘L’-type design worked on by Workshops Core Lab welder Lukasz Malcyzk. His design—named the ‘L’-type after his first name—was inspired by other types obtained for free online from around the world.”

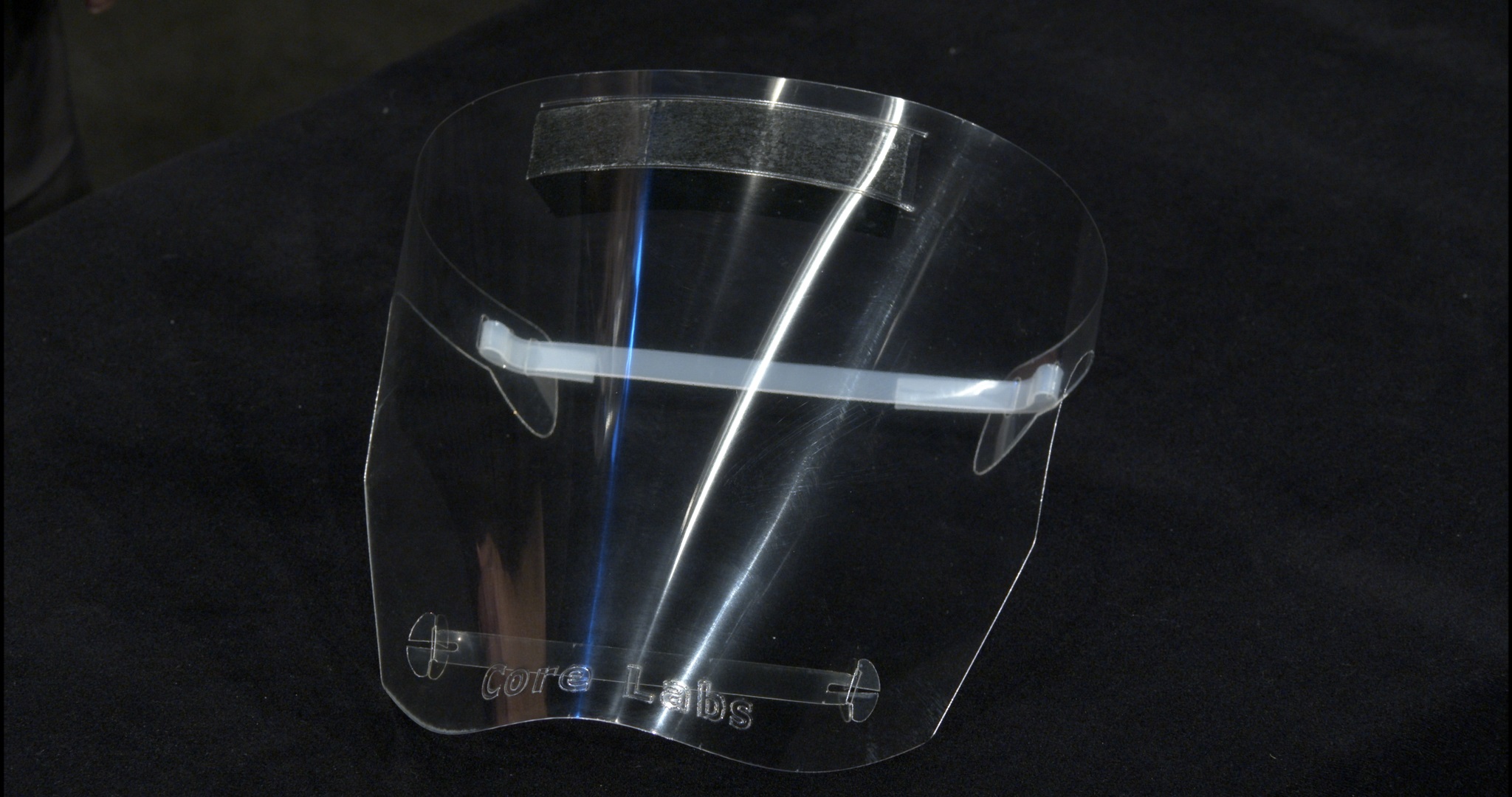

A fully assembled ‘L’-type face shield designed by Workshops Core Lab welder Lukasz Malcyzk is shown here. File photo.

“I drew up the design on SolidWorks, a 3D modeling software program, and produced a drawing exchange format file that is used by the laser cutting machine,” Malcyzk explained. “We are now focusing on only making the ‘L’-type design due to its ease of production.”

“The ‘L’-type design is solely cut on the laser, making it extremely quick and easy to assemble,” he continued. “Two people with one laser cutting machine can produce 250 shields on campus over a five-hour period, meeting our objectives of producing a quickly manufactured, re-usable shield.”

“Feedback from KAUST Health has continued to be very positive,” noted Glasspool. “They have been very grateful for anything we can provide, and they also gave us helpful insight into how to improve the shields—for example, to make them lighter—as the healthcare professionals wear them for long periods of time.”

.jpg?sfvrsn=69b85d77_5)

Workshops Core Lab welder Lukasz Malcyzk (pictured) designed the ‘L’-type face shield, which is now the preferred type for use at KAUST. Photo by Sarah Munshi.

At the end of June, KAUST senior management requested around 2,000 face shields of the ‘L’-type design as the University reopens. The Core Labs’ Lab Equipment Maintenance (LEM) team also carried out safety walkthroughs for face shield use on campus prior to the reopening.

“Eight LEM team members did walkthroughs of the entire University campus while wearing the two different types of KAUST-constructed face shields as a test to see if they’re good for use on a daily basis,” explained Ralph Timmermeester, lead, Physical Technologies Unit, LEM. “We found that both models had advantages and disadvantages. We then gave feedback to the Workshops Core Lab team so they could improve the face shield design.”

“We have so far distributed over 250 face shields of the ‘L’-type and over 100 of the McLaren type to different areas of KAUST, including to the Catalysis Center; the University Library; the Biological and Environmental Science and Engineering division; the Clean Combustion Research Center; and the Analytical Chemistry, Bioscience and Plant Growth Core Labs,” Glasspool said. “We are ready to produce more face shields from our rapid manufacture designs whenever needed.”

The Workshops Core Lab’s laser cutting machine (pictured) is utilized to produce face shields. File photo.

Safety screens for protection

In March, the University requested the Workshops Core Lab team to manufacture safety screens made of Plexiglas acrylic—also called poly(methyl methacrylate) or PMMA—for areas of high customer-staff interaction in the large Tamimi supermarket on campus.

Safety screens have now been placed in similar areas across the campus, such as in the smaller Tamimi supermarket; the greengrocer fruit and vegetable market; the University and Harbor Libraries; the Discovery Square fast food restaurants and mailrooms; the sports recreation facilities; and at the Human Resources and Community Life offices.

Protective safety screens produced in the Workshops Core Lab have been placed around the campus in high-traffic areas, such as in the Community Life offices (shown here). File photo.

Glasspool, Malczyk and Ronan Carolan, Workshops Core Lab senior design engineer, primarily worked on the project, producing the screens by cutting Plexiglas with the laser. If frames were required for the screens, they constructed them from a type of kit called 80/20 that is stored on campus. To test the screens before installation, they assembled them in the Workshops Core Lab and then dismantled and reassembled them on site.

Reception for the safety screens has been positive across the campus.

“As we work on ramping up our service, our priority is for the safety of our staff and the residents and service providers we interact with,” stated Cherine Fayad, manager, KAUST Accommodation Services. “We requested 10 screens, and we put them in areas with high people interaction and in between cubicles for more protection.”

“Having the safety screens provides more protection for our staff and visitors and gives additional comfort during this period,” she continued. “All our interactions with the Workshops Core Lab team for the screens were professional and pleasant, and they swiftly responded to our request by scheduling a walkthrough to understand our requirements.”

“We expect to have more requests for safety screens for front-facing staff areas as these continue opening up over the coming weeks,” Malczyk noted.

Martin Glasspool, Workshops Core Lab lead production engineer, is pictured here behind a safety screen he and the team installed at KAUST’s Human Resources department. File photo.

Working together for KAUST

“My team has been really engaged and extremely eager to help at the drop of a hat, knowing that the face shields and safety screens are making an immediate impact,” Glasspool stated. “So far, we have delivered 2,975 face shields and 123 safety screens.”

“During this stressful time period of the COVID-19 pandemic, producing face shields and safety screens has given the Workshops Core Lab team a sense of satisfaction,” said LaVon Bennett, manager, Workshops Core Lab. “Through offering their services, team members are helping to protect the community and slow the spread of the virus. There are many individuals who have helped in this effort, and they are to be commended.”