By the Workshops Core Lab team and Marian O'Neill

Every innovator knows design is only limited by imagination, just as every creator knows imagination is limited by technology. The Design and Fabrication Core Labs offers the KAUST academic community the opportunity to combine innovation with practicalities.

With 3D modelling the KAUST Design and Fabrication Core Lab offers you the opportunity to design and create precision tools in a variety of materials. Understanding the capacity of electrical and electronics engineering broadens your awareness of the possibilities available to you when customizing equipment. While GD&T (Geometric Dimensioning &Tolerancing), machining and LabView are all vital in informing and streamlining the process.

Basically, our across-the-range selection of training modules allows you access and utilize the precise, cutting-edge technology that ensures an exact, customized realization of the conceptual.

Our winter schedule has just been completed. In total 249 students, researchers, faculty and innovation cluster personnel enrolled for our eight courses. These courses were comprised of; GD&T (geometric Dimensioning and Tolerancing), basic electric and electronics engineering, Introduction to LabView & Data Acquisition, 3D printing, SolidWorks, Manufacturability and Manufacturing & Machining Processes.

GD&T standard workshop

GD&T (Geometric Dimensioning & Tolerancing) standard is a system of symbols, rules and definitions used to define the geometry of mechanical parts. The GD&T standard allows you recognize when a drawing is incomplete or incorrect and teaches you how to calculate limits and fits. For people planning to work in the manufacturing industry this session is extremely beneficial.

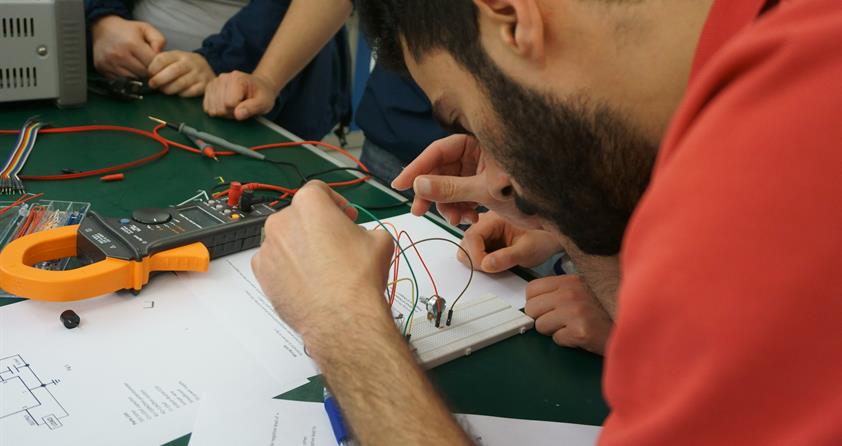

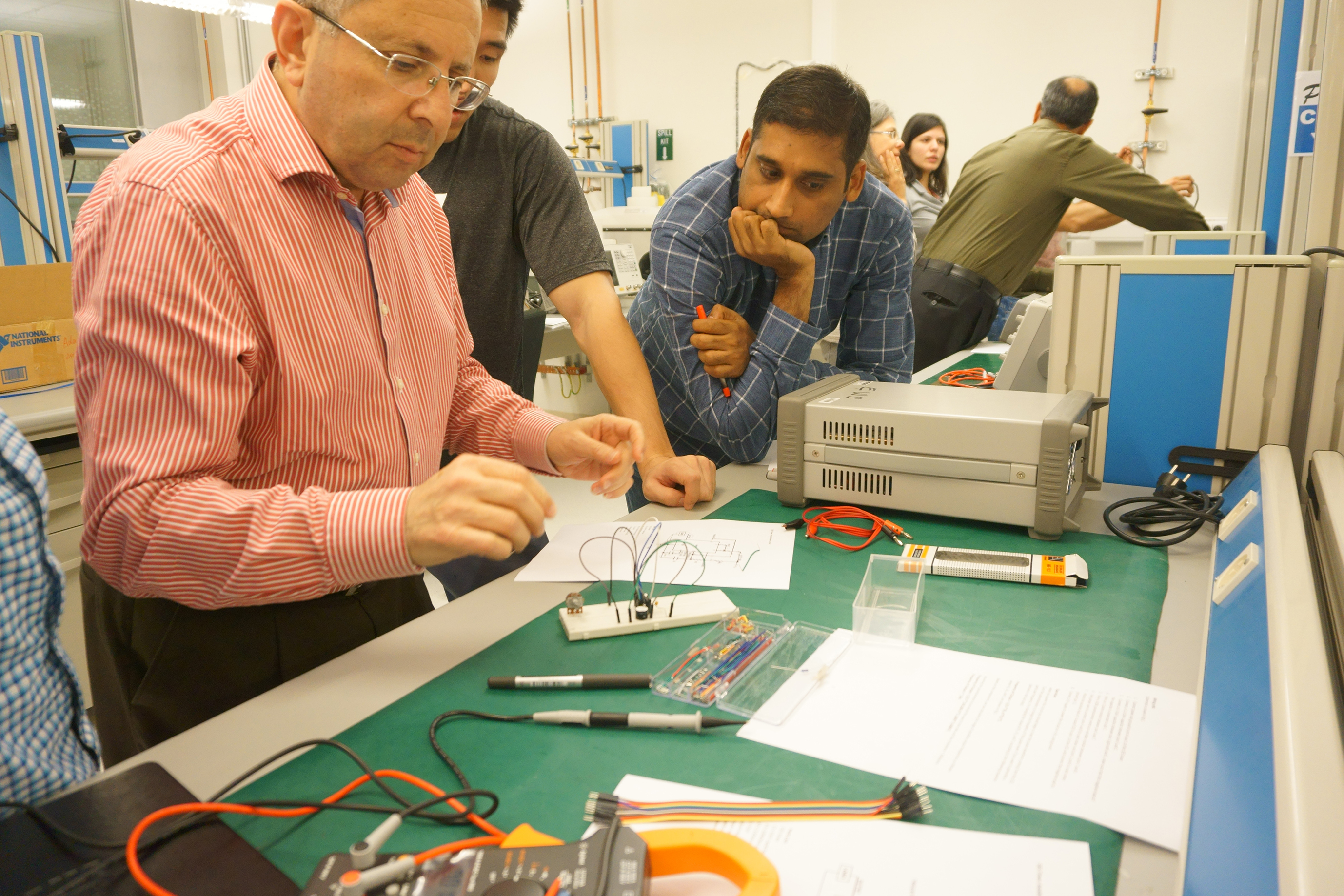

Basic Electrical & Electronics Engineering

The Design and Fabrication Electronics Workshop (EWS) has the resources to provide customized solutions for electrical and electronic requirements. This seminar informed the attendees of our capabilities and highlighted the capacity of this facility.

Introduction to Lab View & Data Acquisition

This Session was hosted by a representative from National Instruments and was extremely sought after with all available places booked out in minutes. LabView is a graphical programming environment used to develop sophisticated measurement, test, and control systems.

3D-Printing

This program trains potential users in how to use the wide range of 3D-Printers available in the Design and Fabrication User-Facility; from Filament 3D-Printers, steriolithography 3D-Printers to metal 3D-Printers. These m/c’s have the capability of 3D-Printing a wide range of materials from PLA, Tough PLA, Nylon, ABS, PE, PE+, and an extensive range of Resins for steriolithography. The training demonstrates how to prepare a solid model from an IGES, STP file to an stl or an equivalent file that can read by the 3D printer.

SolidWorks – Beginners

This is basic SolidWorks training. How to use the sketch tools, the basic 3D modelling tools and of course the concepts of 3D modelling. Also shown are the basic assembly tools.

Both advanced SolidWorks courses were extremely popular, with over 60 participants signing up for them.

SolidWorks Advanced

Advanced 1 illustrates how to use the more complex sketching & modeling tools from the SolidWorks Toolbox, such as 3D-Sketching, patterning, spline tools, using reference geometry tools, Lofting, Wrap tools, Shelling, Draft tools, Surfacing Tools, Sheet-metal tools & assembly tools including mechanical and advanced assembly tools. Preparing drawings and the use of the various formats is also initiated.

SolidWorks Advanced 2

Advanced 2 introduces the use of FEA (Finite Element Analysis) and the capabilities of the SolidWorks FEA module, from Static analysis to Thermal analysis. It also shows how to combine the two areas into a design study. The session explains basic FEA theory, demonstrates the tools available and shows how to qualify a resulting simulation. Advanced 2 initiates the SolidWorks CFD (Computational Fluid Dynamics) module.

Manufacturability and Manufacturing & Machining Processes

The manufacturability course provides our users with a comprehensive overview of our full-service capabilities. The complete scope of our competencies are showcased ensuring users can maximize our facilities. Delivered by one of the Design and Fabrication Core Labs’ Master machinists this courses also explains the basics of metal-forming, how to run a component assembly design as simply as possible, the importance of applied tolerances and of picking suitable materials for particular applications.

Our next program of courses will begin early next semester. We have listened to our students’ feedback and, in many cases, have adapted our courses in compliance with their, very sensible, suggestions. Mostly they have asked for more; longer seminars and extra courses.

Enrollment will open from the start of next semester.

Please contact ronan.conlan@kaust.edu.sa for further information.