By the Workshops Core Lab team, David Murphy and Marian O'Neill

Glass has a long history in promoting scientific development, and its core properties—non-volatility, heat resistance, malleability and a non-porous nature—render it an ideal material for scientific experiments. From the thermometer to the light bulb to fiber optics, glass has fundamentally changed how we view and interact with our world.

The scientific glassblowing profession emerged to bridge the gap between the material and the application. As the level of scientific research continues to grow apace at KAUST, the demand for specialized equipment grows in tandem, specifically scientific glassware products. To meet the continuing demand for scientific glass products, the KAUST Workshop Core Lab recently opened an upgraded version of the scientific glassblowing workshop.

The new facility has introduced a broad range of highly advanced equipment, including large and small precision lathes, optical polishing equipment, gold and platinum coating machines and a quartz annealing oven. This state-of-the-art facility and its expert glassblowers are now available to deliver bespoke scientific glass equipment to the KAUST academic community.

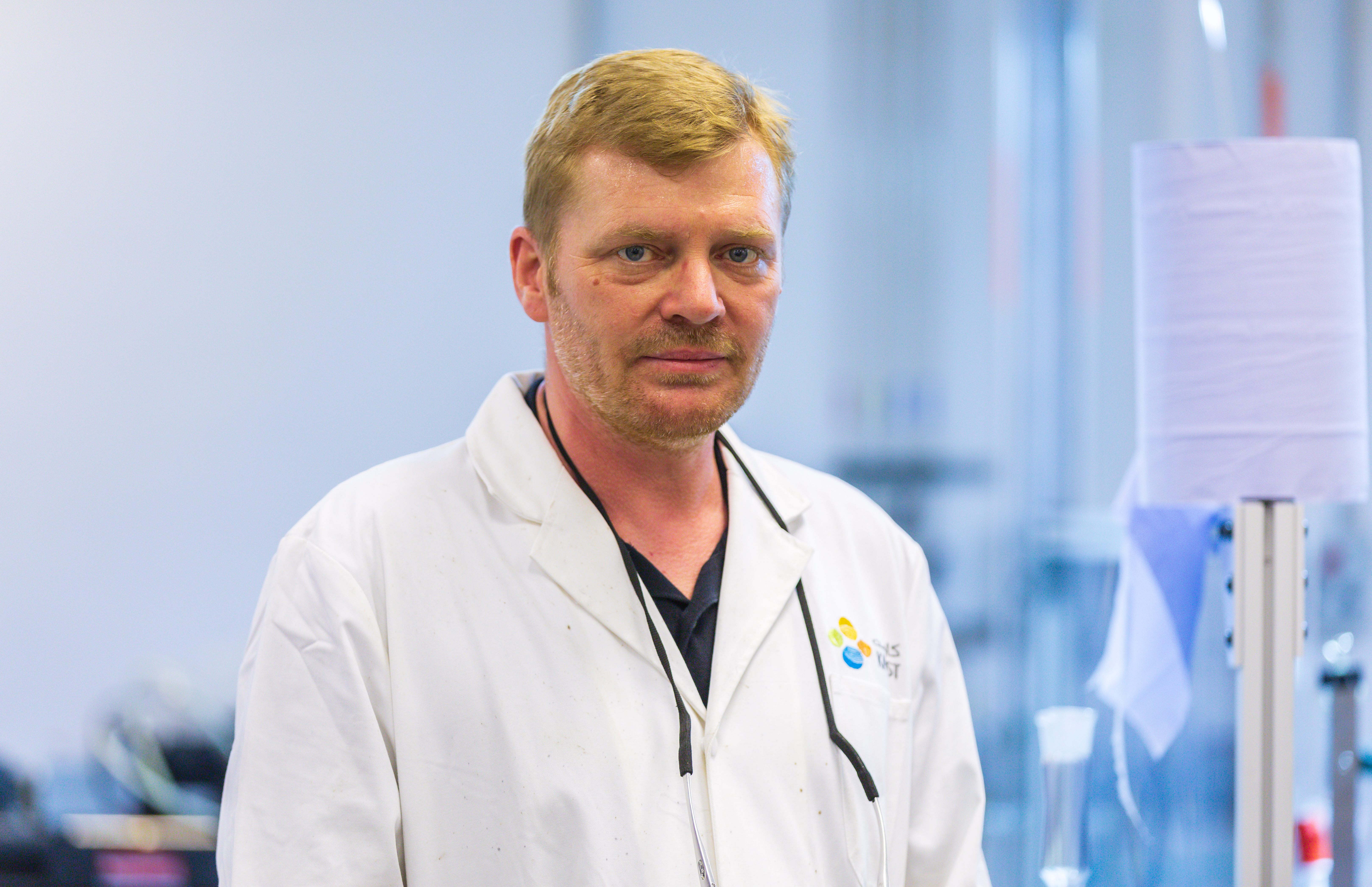

Ernest Neil Davison, a senior scientific glassblower, works in the KAUST scientific glassblowing workshop on producing glassware for the KAUST research community. Photo by Asharaf K. AbdulRahman.

The demand for specialized equipment

In order to fully facilitate the exact needs of KAUST researchers, the University's scientific glassblowing workshop works with borosilicate and quartz glass; it is the only facility in the region to do this. Borosilicate glass has a high chemical resistance and excellent thermal capacity, while quartz is superior in purity, transmits ultraviolet light and can withstand temperatures of 1,200°C.

On a daily basis, two of the University's most skilled tradesmen and senior glassblowers—Ernest Neil Davison and Emilio Harina—can be found in the glassblowing workshop creating the latest designs from prototype paper sketches, developing them into the intricate and functional end product. Davison believes that—thanks to the latest cutting-edge equipment and technology available to him and Harina—the majority of global universities would struggle to match the quality craftsmanship produced on campus.

"You haven't got machinery like this anywhere else. We can produce high-quality inductively coupled plasma mass spectrometry (ICP-MS) and optical emissions spectroscopy (OES) glassware here. I don't know of any university in the world that makes the kind of glassware we produce in-house," Davison emphasized.

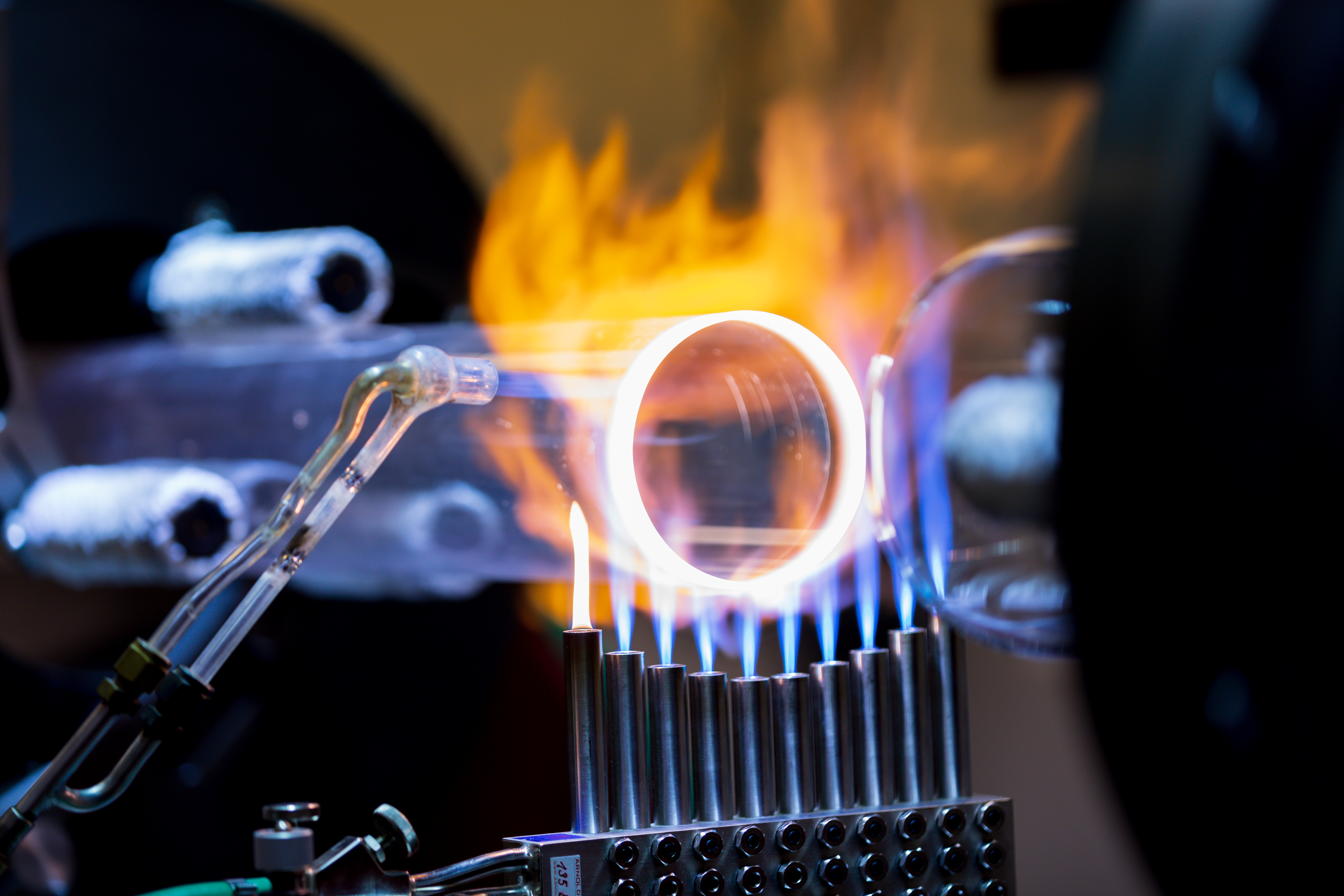

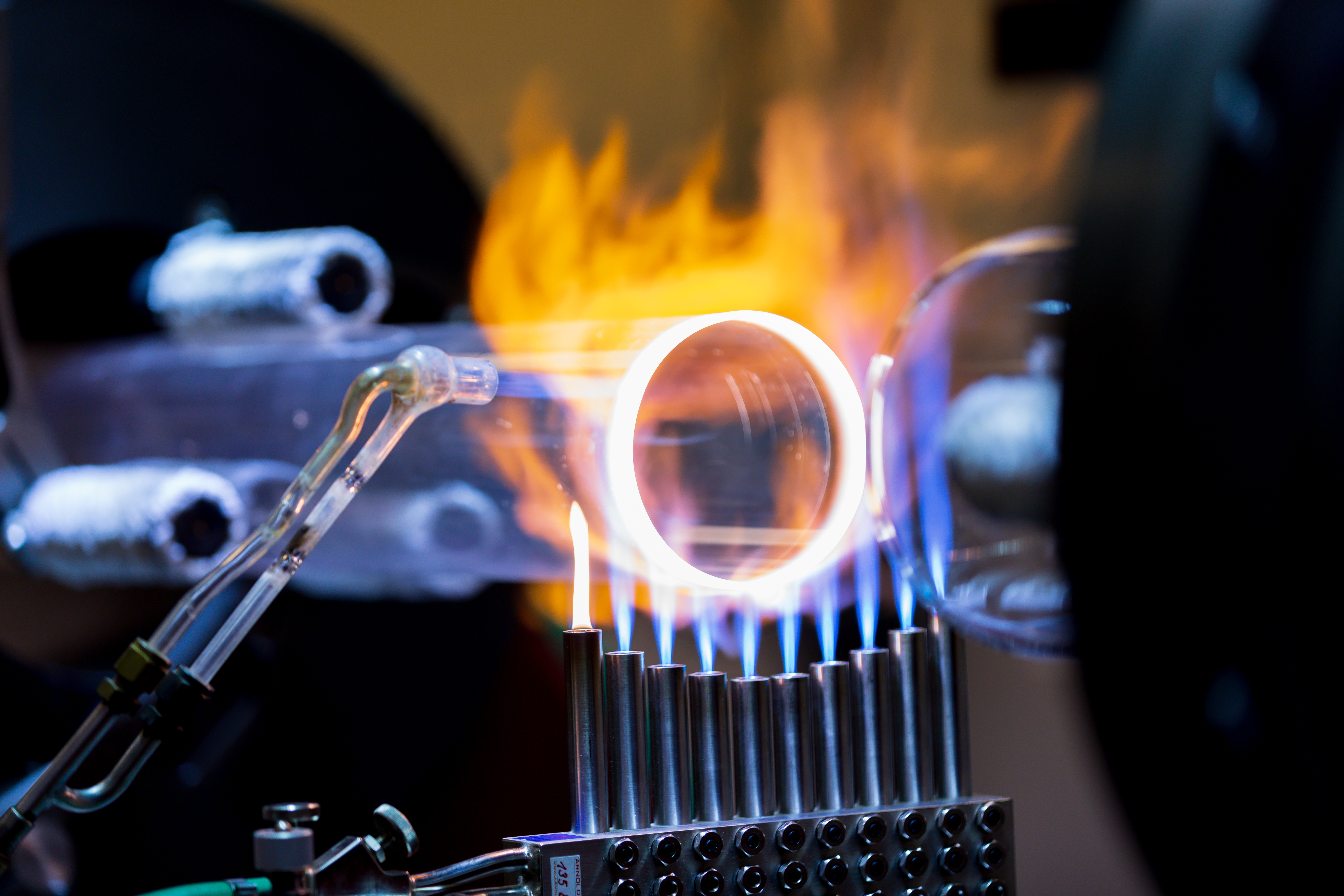

The University's scientific glassblowers Ernest Neil Davison and Emilio Harina work together in the KAUST scientific glassblowing workshop, part of the Core Labs, on creating glassware for the research community. Photo by Asharaf K. AbdulRahman.

A highly skilled practice

Scientific glassblowers are highly skilled craftsmen with a thorough understanding of research processes, and they have long been recognized as the artisans of the scientific world. The modern mass production of generic laboratory equipment has required them to further hone their skills. Today, scientific glassblowers concentrate on the intricacies of more precise apparatuses. Their work demands dexterity, creativity and scientific awareness.

Davison, who joined KAUST in 2015, is well-versed in the aforementioned skills. He began his career in glassblowing 30 years ago in his hometown of Sunderland in the northeast of England. Sunderland has a proud history of glassmaking, and it was in one of the city's most well-known workshops that Davison began his five-year glassmaking apprenticeship.

"When I left school in 1988, I got an interview with a local company called Dunelm Glass. At Dunelm, I created scientific glass, but we mainly focused on making things like fishermen's anglers, model airplanes and products for jewelers," Davison said.

"The job hasn't changed since I started," he noted. "You're using the same medium, and the tools that were used are pretty much the same. The only difference nowadays is that some companies now have lathes with water jet capabilities that can cut glass in precision shapes. But the trade is exactly the same—today's apprentices will learn the same skills I learned back in the 1980s."

The University's scientific glassblowing workshop produces glassware for the KAUST research community. Photo by Asharaf K. AbdulRahman.

Nurturing in-Kingdom talent

In the coming months, the scientific glassblowing workshop will offer an apprenticeship program for local Saudi students, ensuring that the age-old skill survives to continue assisting the work of future researchers. A five-year apprenticeship is currently in the works, where local students will learn about the history of glass to finding out how to create their own scientific glassware.

"The students will begin by learning about the everyday use and history of glass, and from there the students will learn how to prepare the glass. Once they can prepare the glass for me—through cutting, grinding, polishing, washing, etc.—that's when I know they're ready for the next level; to prepare the gas and to put all these pieces of glass together," Davison outlined.

"The program will take place over a five-year period and it will be a hard and long process, but it will also be a rewarding process. In my apprenticeship, I spent my first six weeks in the workshop just watching and monitoring my mentor at Dunelm Glass. In that time, I never operated a piece of machinery—I just watched and learned," Davison said.

"My mentor used to say, 'Glassblowing is like balancing a ball bearing on a ballpoint pen.' In the beginning, it's nigh on impossible, but you learn. It can take upwards of 10 years to reach my level of ability," he emphasized.

Davison feels it would be an honor to play a part in introducing glassblowing to a brand new market in Saudi Arabia.

"Our trainee glassblowers will come with fresh ideas coupled with a different mindset. At KAUST, we will get to introduce Saudi students to an old skill into which they can add all sorts of new ideas and techniques. Our apprentices will be trained right here in the Kingdom—which is exciting," he noted.

Emilio Harina, a senior scientific glassblower, works in the KAUST scientific glassblowing workshop on producing glassware for the KAUST research community. Photo by Asharaf K. AbdulRahman.

A revitalized trade

Davison and Harina are rarely fazed by the projects assigned to them daily from the KAUST academic community.

"You make so many things that, when you get to my stage, you get used to one task as much as the next. But sometimes you get taxed with something out of left field and you're really left scratching your head because you might not have made the product in 10 years. Then you have to remake an old design—you have to make it brand new again," he noted.

"I believe that glassblowing is going to regain popularity in the next 10 years," Davison said. "When I first began my career, virgin polypropylene [plastic] was causing a lot of redundancies in glassblowing workshops because it didn't need an exhaustive set of skills to produce. It was readily available, mass-produced and—more importantly—it was cheaper than hand designed scientific glassware."

"Once upon a time, with cheap injection molding you could afford to use a test tube once and then throw it away—you can't do that now—it would be frowned upon. There is now a drive to be 'green'—with a handmade glass test tube, it can be reused five, 10 or 20 times. Eventually, it will break, but you can recycle it—you can repair it and you can use it again," he acknowledged. "It will be exciting to see where the field takes us in the coming years, especially with our future trainees in the Kingdom."