By the Workshops Core Lab team and Caitlin Clark

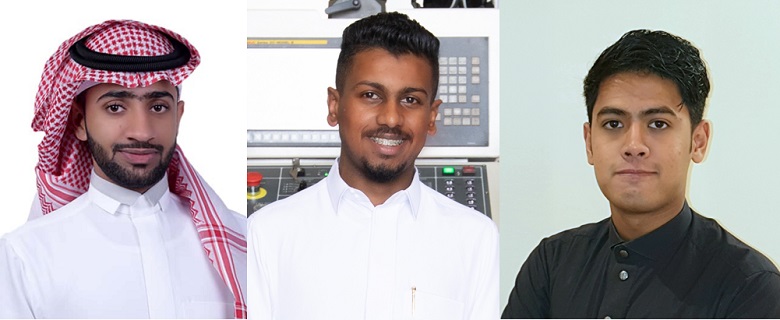

For Mohammed I. Khalil, Mohammad A. Somer and Bakur A. Fadil, 2020 graduates of the KAUST Core Labs’ second Machinist Development Apprenticeship Program (MDAP), exciting opportunities await in the Kingdom’s manufacturing field.

“MDAP contributes directly to achieving Saudi Arabia’s Vision 2030 by training young Saudis on the most advanced technologies and equipping them to work in manufacturing industries in the future,” noted Fadil.

“The 18-month-long program aims to develop a world-class machinist workforce through in-depth training opportunities in the Workshops Core Lab, a state-of-the-art work environment,” Osman El-Negery, master machinist, supervisor of the Harbor Workshop and MDAP administrator, said. “Our ability to successfully provide a skilled, trained and committed workforce—with team players who are also capable of thinking outside the box—will most certainly be an asset for the Kingdom.”

The initial concept for MDAP came into existence in the Core Labs in early 2015 and was spearheaded by Justin Mynar, KAUST associate vice president for research and executive director of the KAUST Core Labs and Research Infrastructure. In creating the program, the University established a collaboration with Yanbu Industrial College, from which all of MDAP’s participants were recruited.

Apprentice Bakur Fadil inspects a 3D-printed prototype part in the University’s Prototyping Core Lab. File photo.

MDAP welcomed its first batch of apprentices to campus in the summer of 2017 to begin the program. Apprentices Ali Al-Frshuti, Yaseer Al-Omrany and Muath Alamri completed MDAP in January 2019, taking up positions as technicians and a junior machinist, respectively, in the Workshops Core Lab.

Khalil, Somer and Fadil started MDAP in January 2019 and graduated on August 17 this year. Their graduation was celebrated in an online ceremony on the same day, which was attended by the apprentices, their families, members of KAUST’s senior leadership, including Mynar; Samer Samman, chief Human Resources officer; and Professor Donal Bradley, vice president for research; Core Labs directors and staff members; and Dr. Fahd M. Al-Ofie, director of Yanbu Industrial College.

Developing outstanding machinists

Before joining MDAP, the current and first batch of apprentices completed their associate’s degrees in manufacturing engineering technology at Yanbu Industrial College.

“The success of the previous apprentices encouraged me and my fellow participants to apply for the program,” Fadil stated. “After finishing college, I was looking for an apprenticeship program to help me convert my academic knowledge into marketable job skills—so KAUST was the perfect choice for me.”

“I already knew of KAUST as a place that enthusiastically encourages growth through education, training and the use of its vast resources, making me excited to join the program,” added Khalil.

“MDAP works on developing machinist general knowledge and skills,” El-Negery said. “Therefore, the apprentices are educated on all types of equipment and on the facets of its use. To accomplish this, the program includes classroom instruction and on-the-job training.”

“Apprentices are provided with in-depth training that ranges from the designing stages to the manufacturing of parts using state-of-the-art computer-aided design (CAD) and computer-aided manufacturing (CAM) software and manufacturing equipment, such as computer numerical control (CNC) milling, CNC turning, CNC laser cutting and CNC water jet cutting machines,” he continued. “They work in the Workshops Core Lab’s Machining section, which includes the Harbor and Central Workshops.”

The Core Labs’ second batch of Machinist Development Apprenticeship Program participants celebrated their 2020 graduation in an online ceremony held on August 17. File photo.

Based on the daily job requests received in the Workshops Core Lab, the apprentices were assigned with jobs to complete. To enhance their training tasks, they were also given different weekly mentors by El-Negery, and they shadowed each mentor.

“The apprentices had to first evaluate each job; assemble the materials and tools needed to process the work; write the CNC program, if required; and machine the parts or components to completion, as per the design and specification,” El-Negery said. “The completed part was then sent for final quality inspection.”

“As a beginner machinist, at first I was afraid while working on the big cutting machines,” Somer noted. “However, I gained confidence and quickly began enhancing my experience and skills in manufacturing.”

Fadil agreed, stating: “The beginning of the program was the most difficult part. When I started to work on the machines, I broke many cutting tools, and I ruined many parts. At that time, I thought I’d never be a skilled machinist, but Workshops Core Lab mentors Muath Alamri and Constantin Moraru guided me to specific techniques to understand why the tools broke, enabling me to become more skilled.”

Apprentice Mohammed Khalil is pictured in the Central Workshop, where he prepares a job by reading a drawing to find the best methods and tools to machine a part. File photo.

MDAP also includes English courses and online soft skills classes, such as Microsoft Excel training and cultural understanding courses.

“The English classes had a great impact on me and really assisted with my communication with others, especially in the laboratory environment,” Khalil said.

Building careers

“The skills I’ve learned during MDAP have a direct impact on my future career,” noted Fadil. “One goal I aim to achieve is to secure a permanent position in a massive research facility, such as a NASA or Boeing facility. And, after some time working in a research facility, I might even be able to train apprentices.”

“Manufacturing is growing in Saudi Arabia, and the field requires a workforce of experts,” Somer said. “I plan to use my skills from MDAP to find a machinist job and apply what I’ve learned to gain more experience in the manufacturing field. I also hope to one day start a manufacturing business.”

“MDAP has set us on the right path, and we’re now equipped with the right knowledge, skills and confidence to set brave goals and achieve them,” Fadil added.

In the Central Workshop, Bakur Fadil inspects a part to ensure it meets engineering specifications after the computer numerical control machining phase. File photo.

“With the skill set and experience acquired at KAUST, I’m confident our MDAP graduates have what they need to find jobs and create a bright future in the manufacturing industry,” stated El-Negery. “To continue our important program, we hope to have a third batch of apprentices begin MDAP in early 2021.”

“For participants of MDAP and the Workshops Core Lab’s Glassblowing Apprenticeship Program, KAUST is the perfect environment in which to develop exceptional machinists and scientific glassblowers for the Kingdom’s future,” said LaVon Bennett, manager, Workshops Core Lab.

Celebrating achievements

During the MDAP virtual graduation event, KAUST leadership congratulated the apprentices on their achievements and praised Yanbu Industrial College’s leadership in continuing to champion the program through their collaboration with the University.

“Yanbu Industrial College and KAUST [have a commitment] to achieve our shared vision in developing careers for young machinists in manufacturing technology,” Mynar stated. “I am very optimistic for the future of [MDAP]. Together, KAUST and Yanbu Industrial College are contributing to the development of young Saudi talents, in line with the 2030 Vision, and I look forward to our continued collaboration.”

Bakur Fadil works in the Prototyping Core Lab on the MakerBot 3D printer, monitoring the first layer of printing and the filament’s flow from the printer’s extruder to deliver a successful 3D-printed part. File photo.

“The Core Labs is not a stranger to strategic initiatives that are impactful to KAUST and to the Kingdom,” noted Samman. “[The apprentices’] graduation is also a celebration of the successful collaboration with Yanbu Industrial College. We value and cherish the partnership and we want it to continue into the future. The dedication of the team from the Core Labs and Yanbu Industrial College led to [the apprentices’ success].”

“Training highly qualified, highly skilled machinists who are capable of making things is one of the most important things for a country to build its technological future,” said Bradley. “You apprentices have very bright futures ahead of you. Take the experience [from KAUST] and make good use of it for yourselves, your families and your country.”